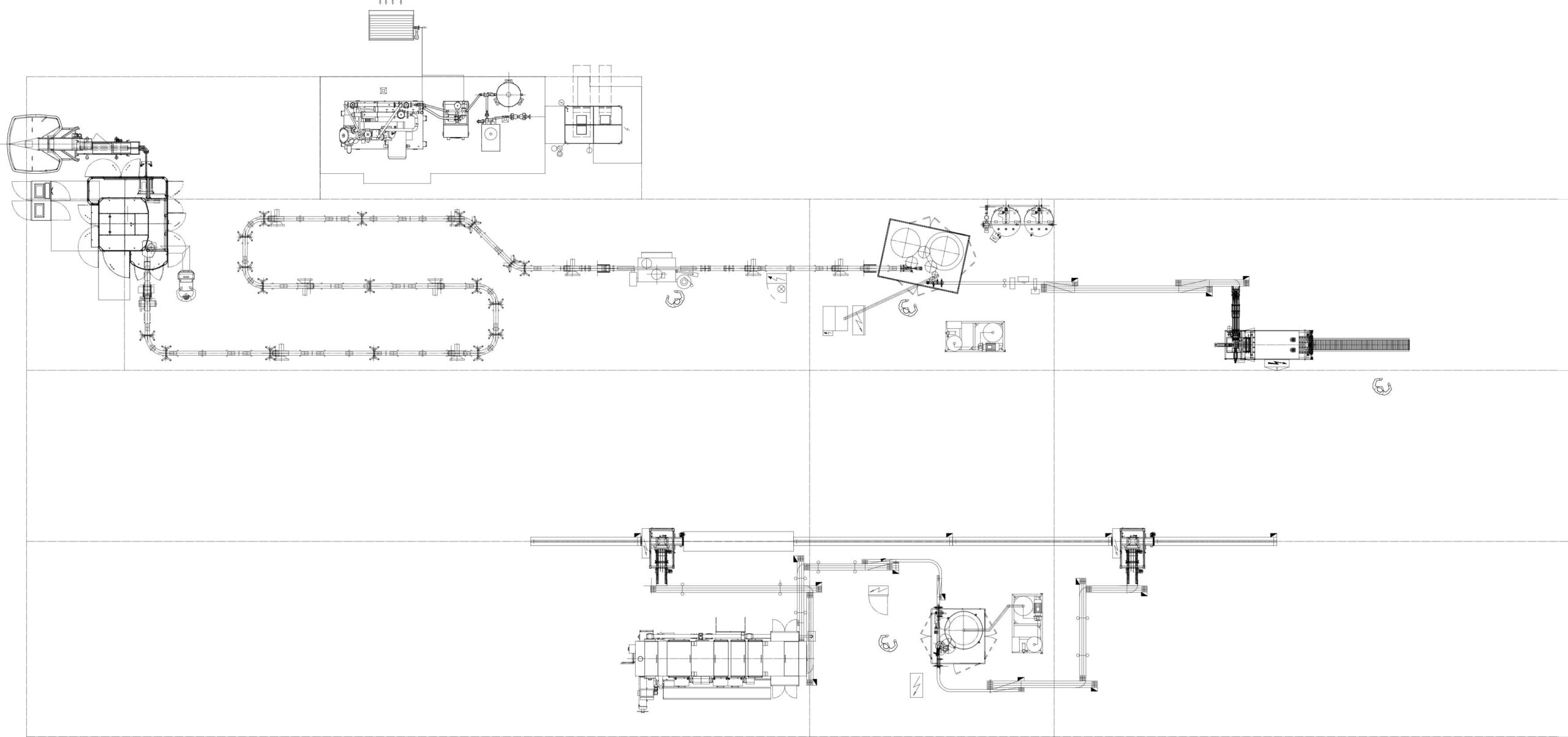

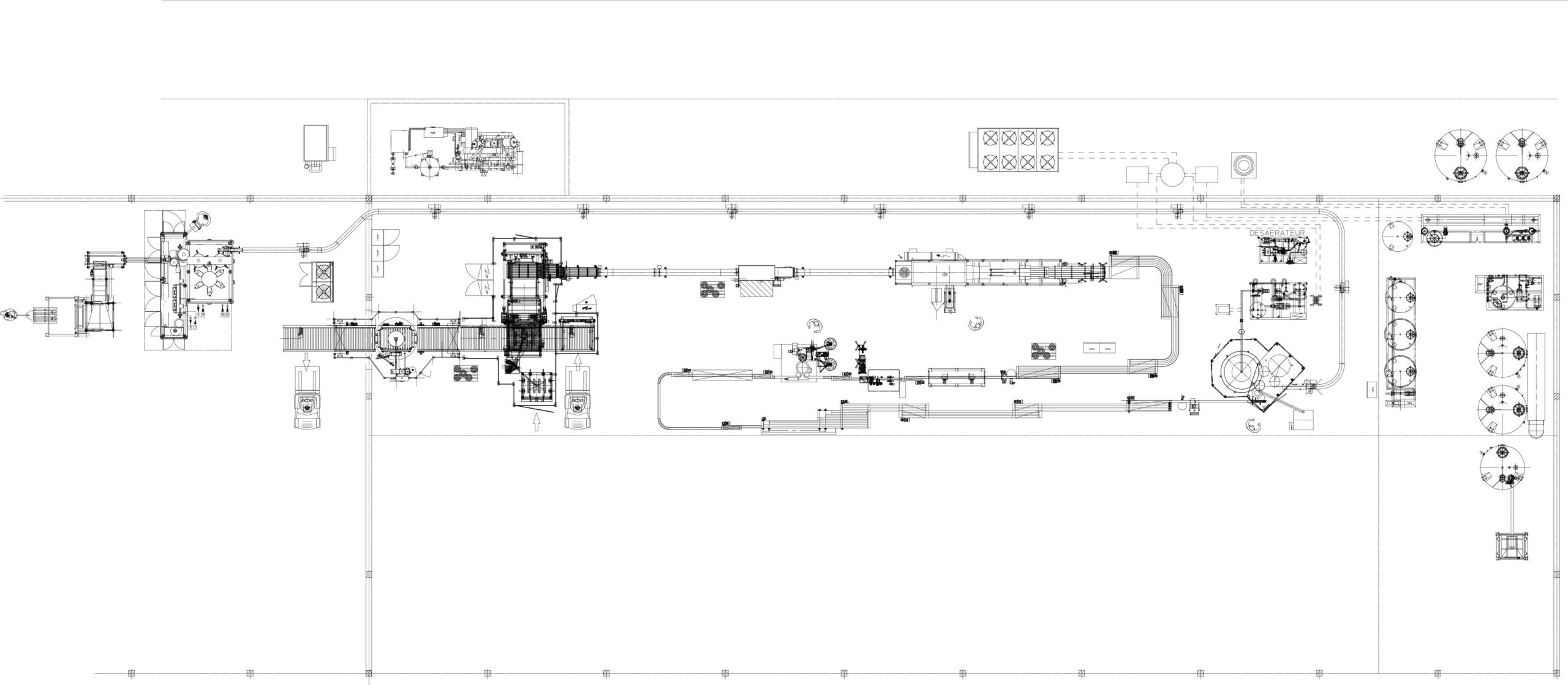

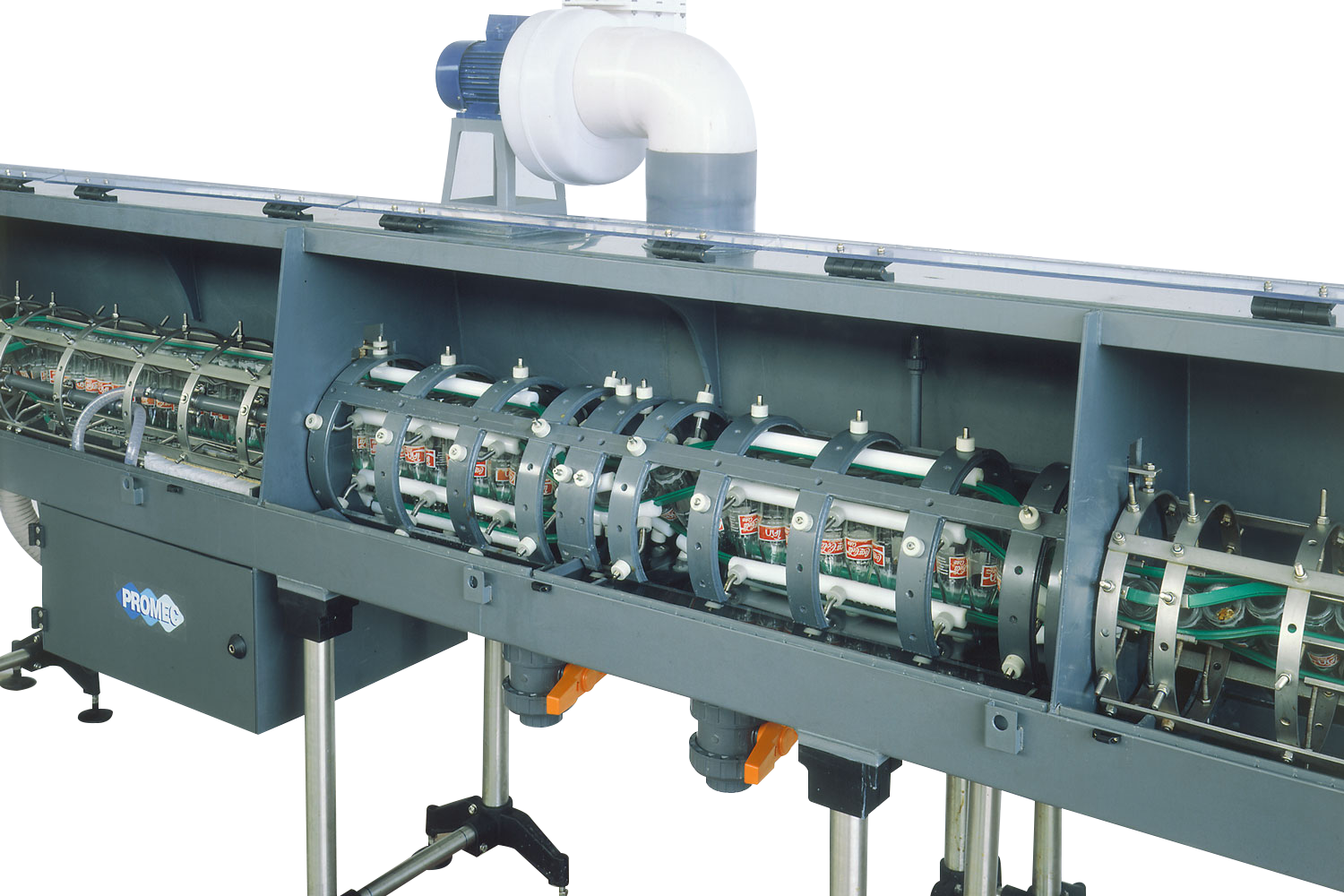

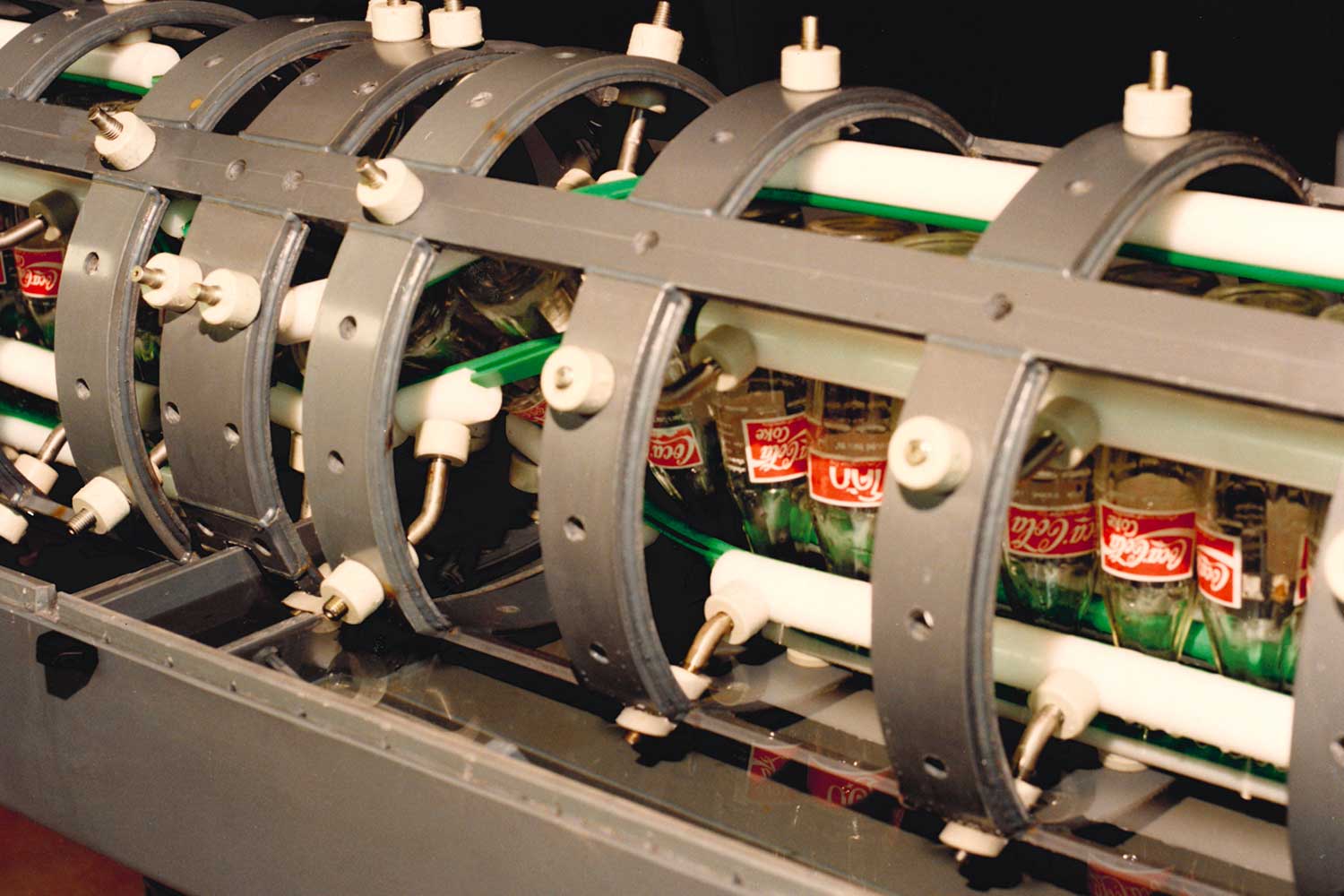

Detail of machine interior

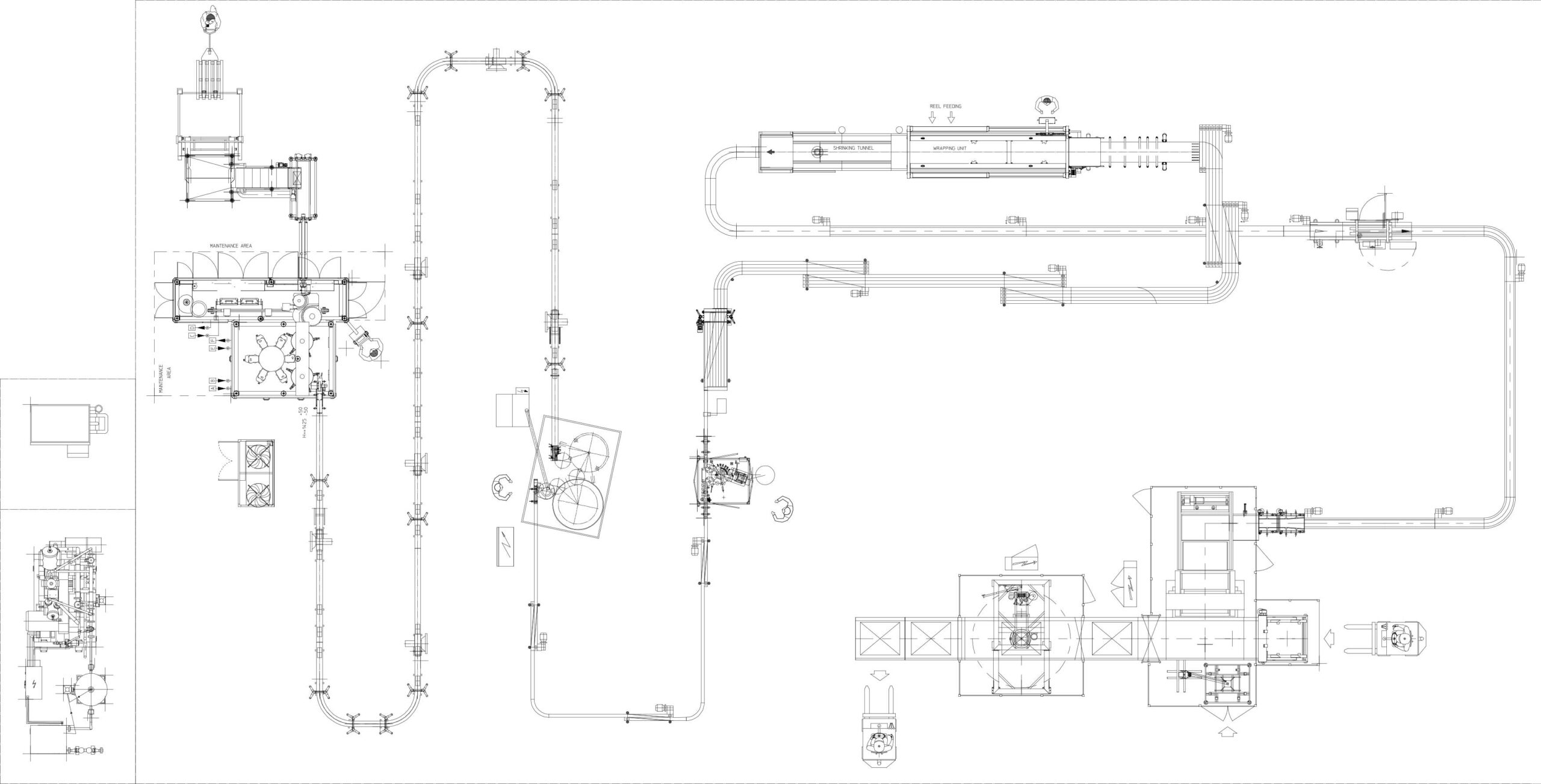

This machine belongs to the Twistline class and is designed to eliminate the residues of ferric oxide (rust) present in the bottlenecks of recycled glass bottles with crown caps. After being rotated in the input twist, the bottlenecks are inserted into a concentrated hydrochloric acid solution for a sufficient period to stabilise the ferric residue.

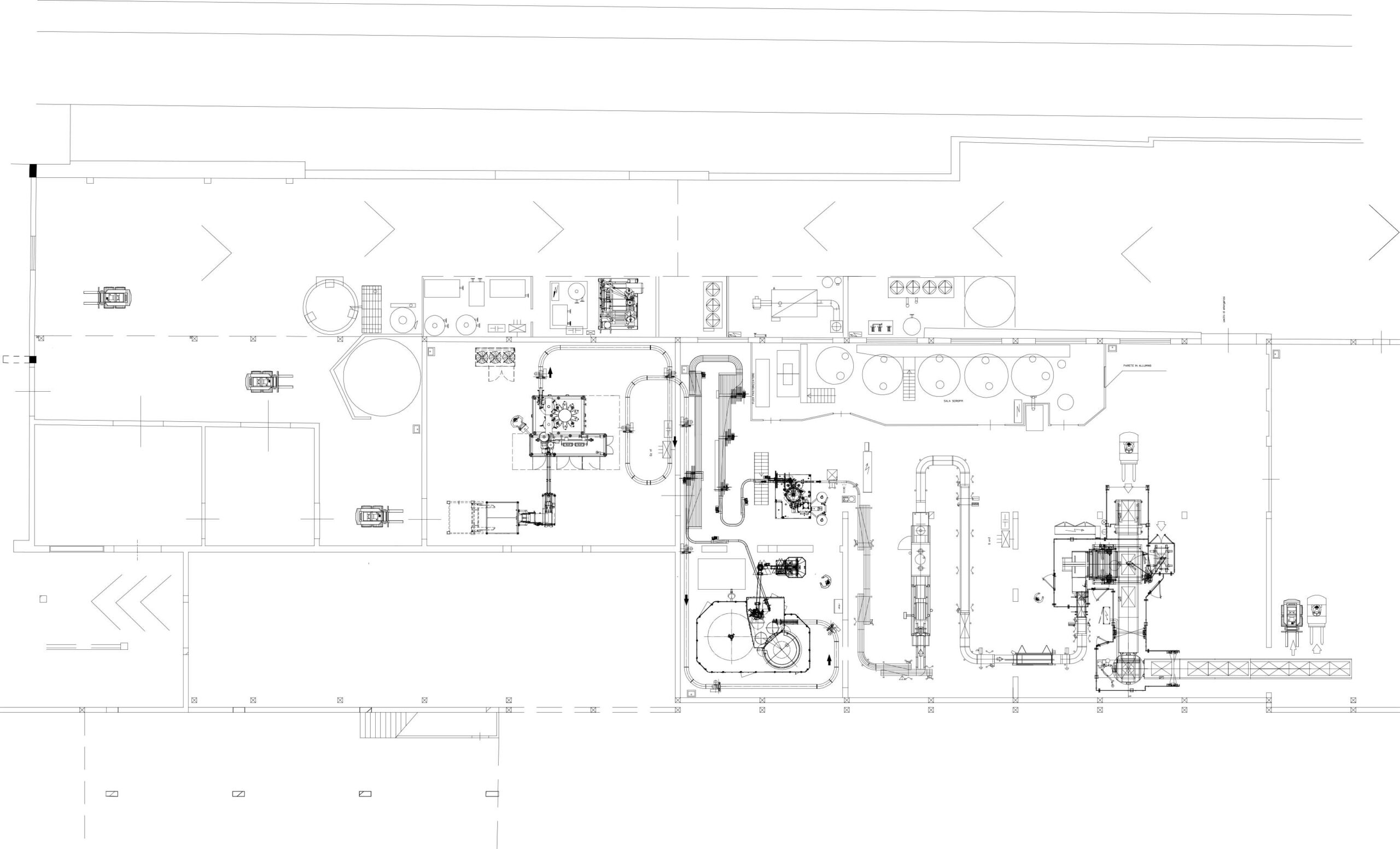

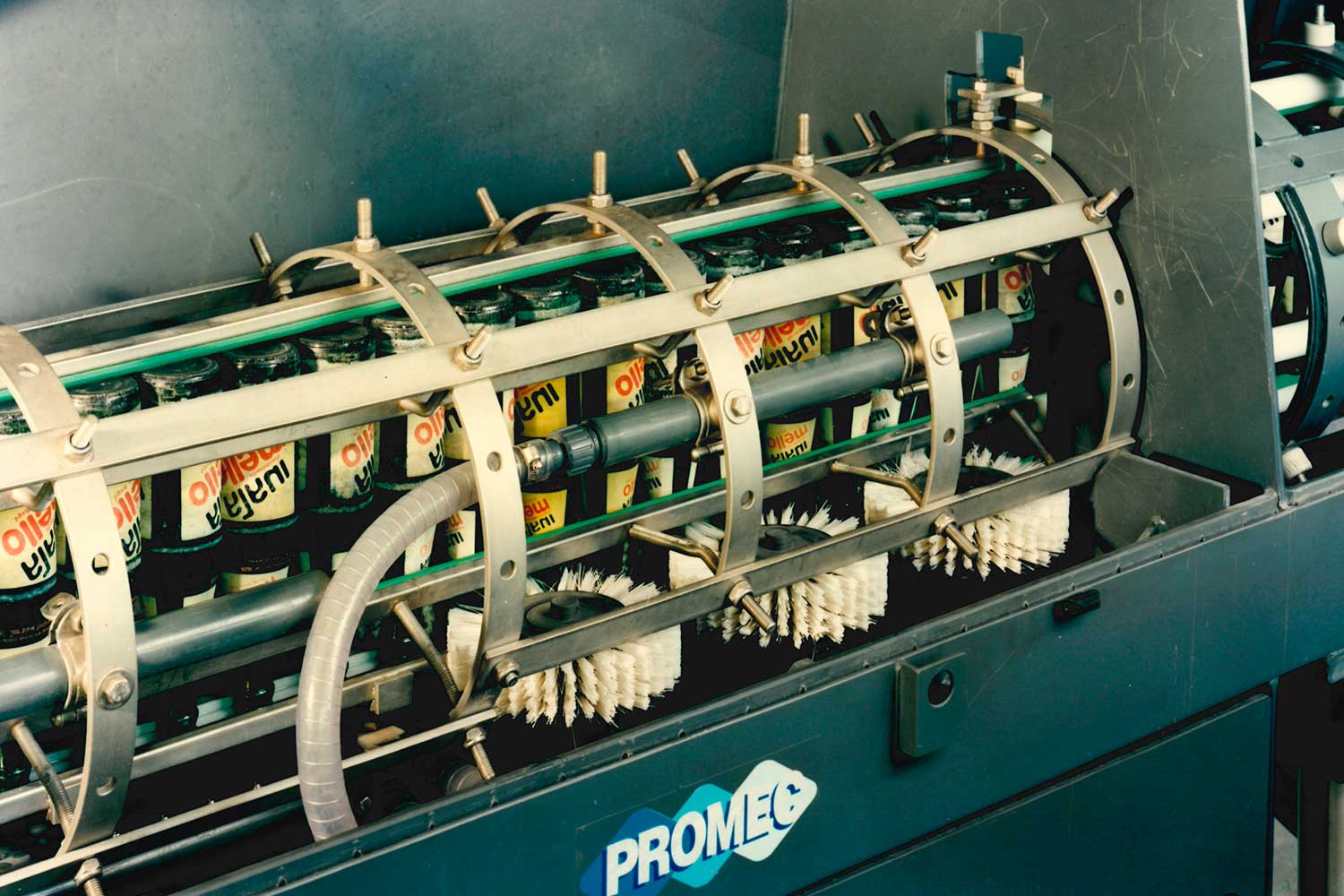

The bottles are conveyed to a section equipped with special rotary brushes which, by abrasion, clean the bottlenecks and are complemented by another high-pressure water jet rinse. The combined action of brushing and pressure washing leads to removing any existing rust rings from bottlenecks.

The treatment cycle is completed by a procedure where bottlenecks are rinsed in disposable water to eliminate the remaining residues.

Since hydrochloric acid is highly corrosive (and toxic) the machine is completely manufactured in acid-proof plastic material and type HASTELLOY steel.

A hood allows evacuation and neutralising the smoke produced inside the machine.

Twist detail

Brushes detail

Fill in the form to receive all the details you need about all Promec bottling machinery

FILL IN THE FORM