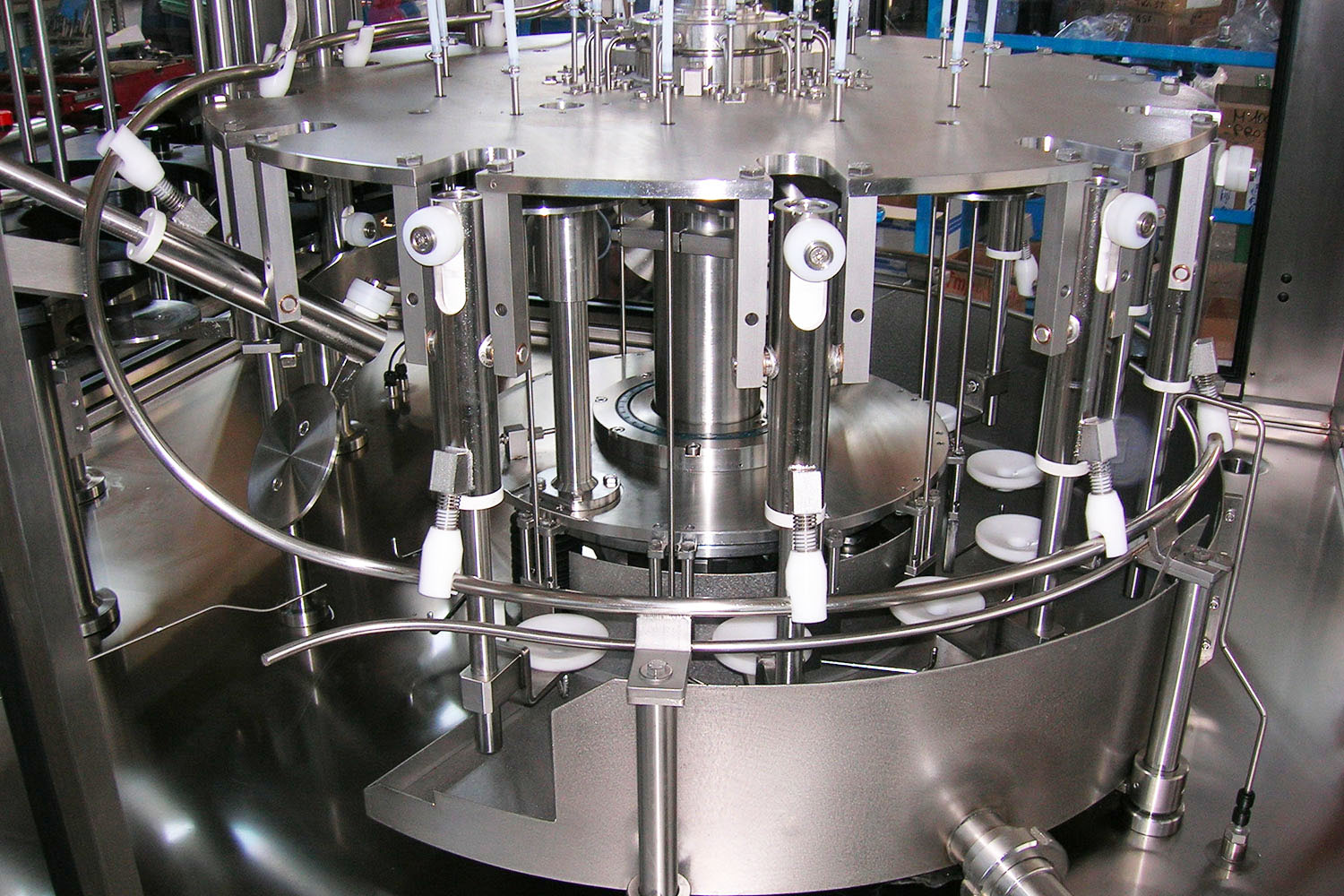

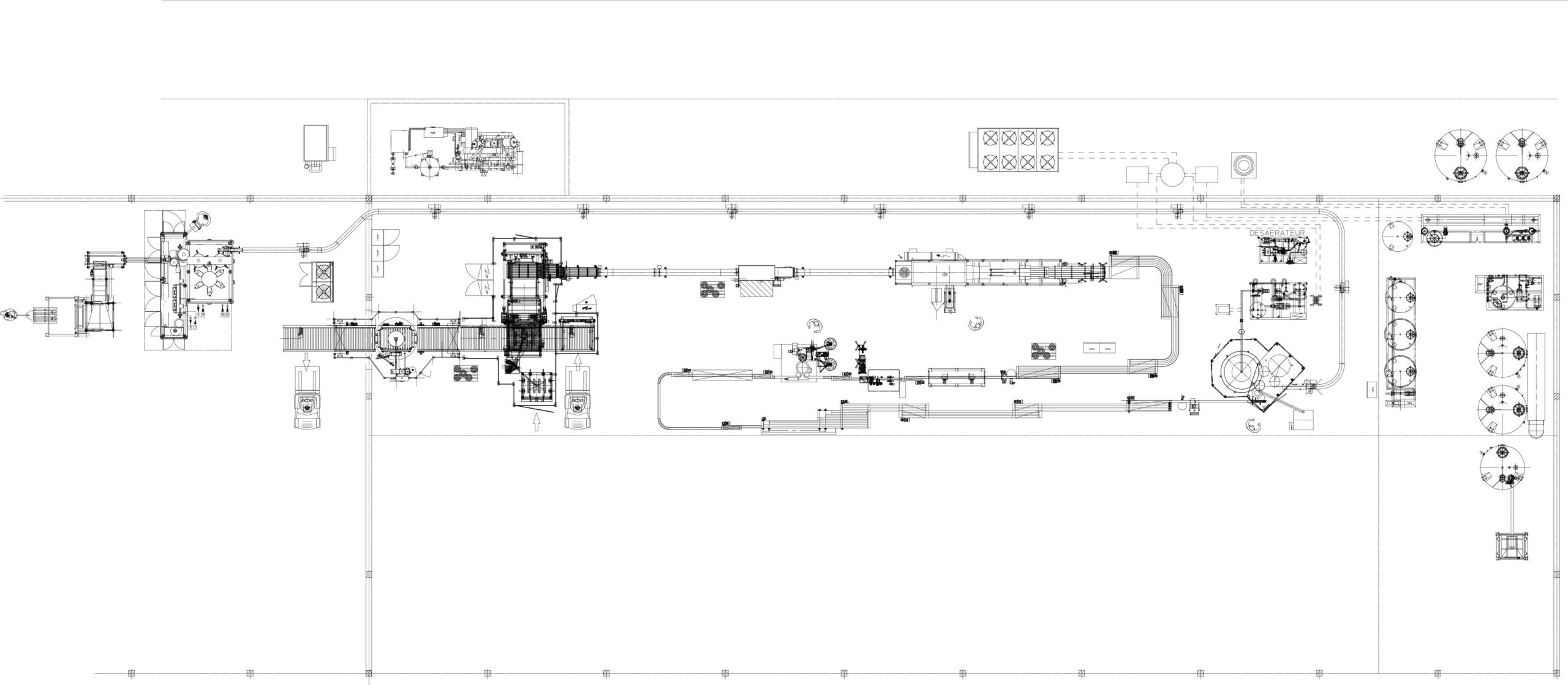

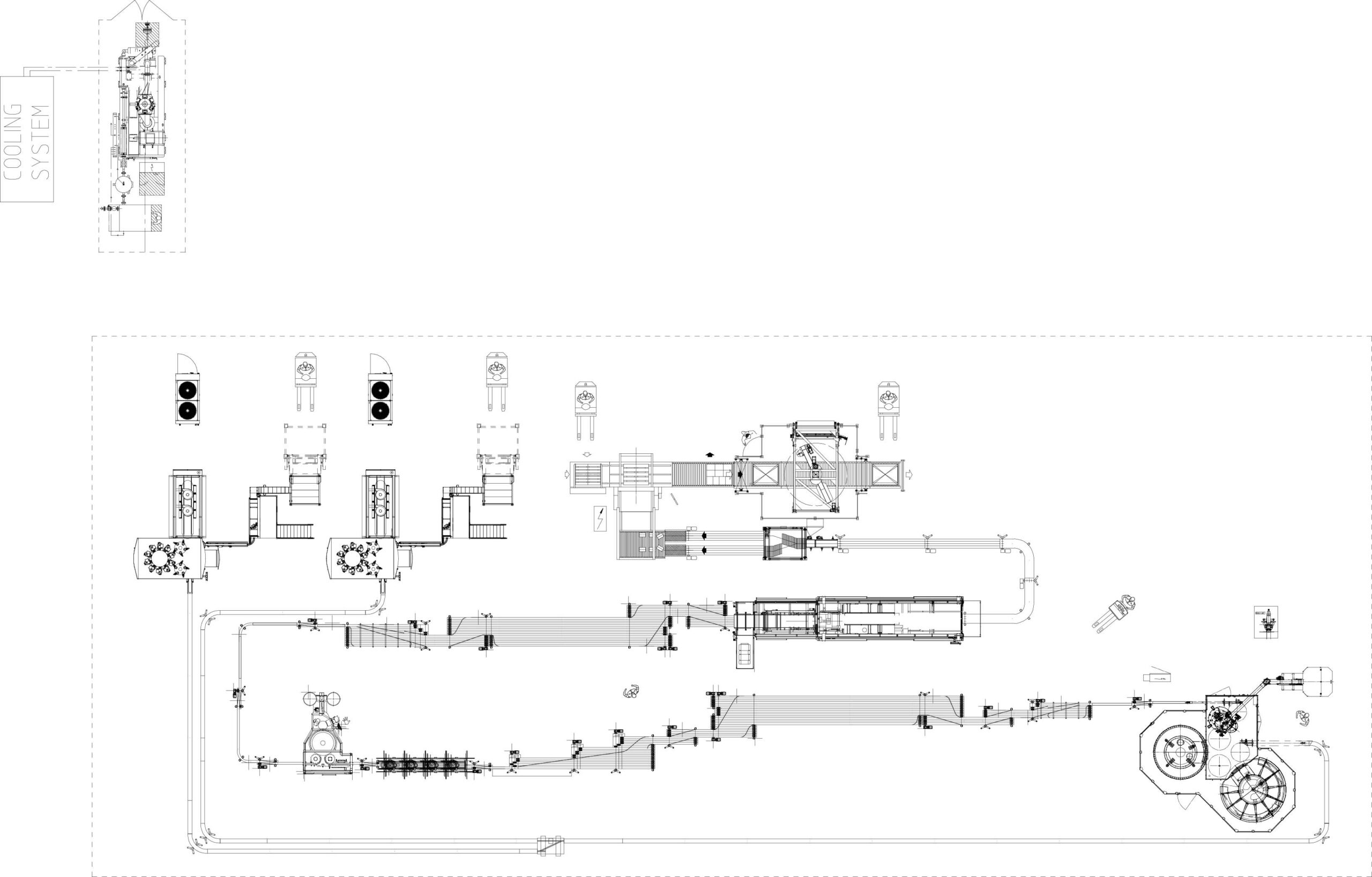

Rotoax is a rotary rinser blower and steriliser, characterised by grippers which hold the bottles along their axis, between a lower bearing plate to which the bottle is driver by the entry star and an upper centering cup.

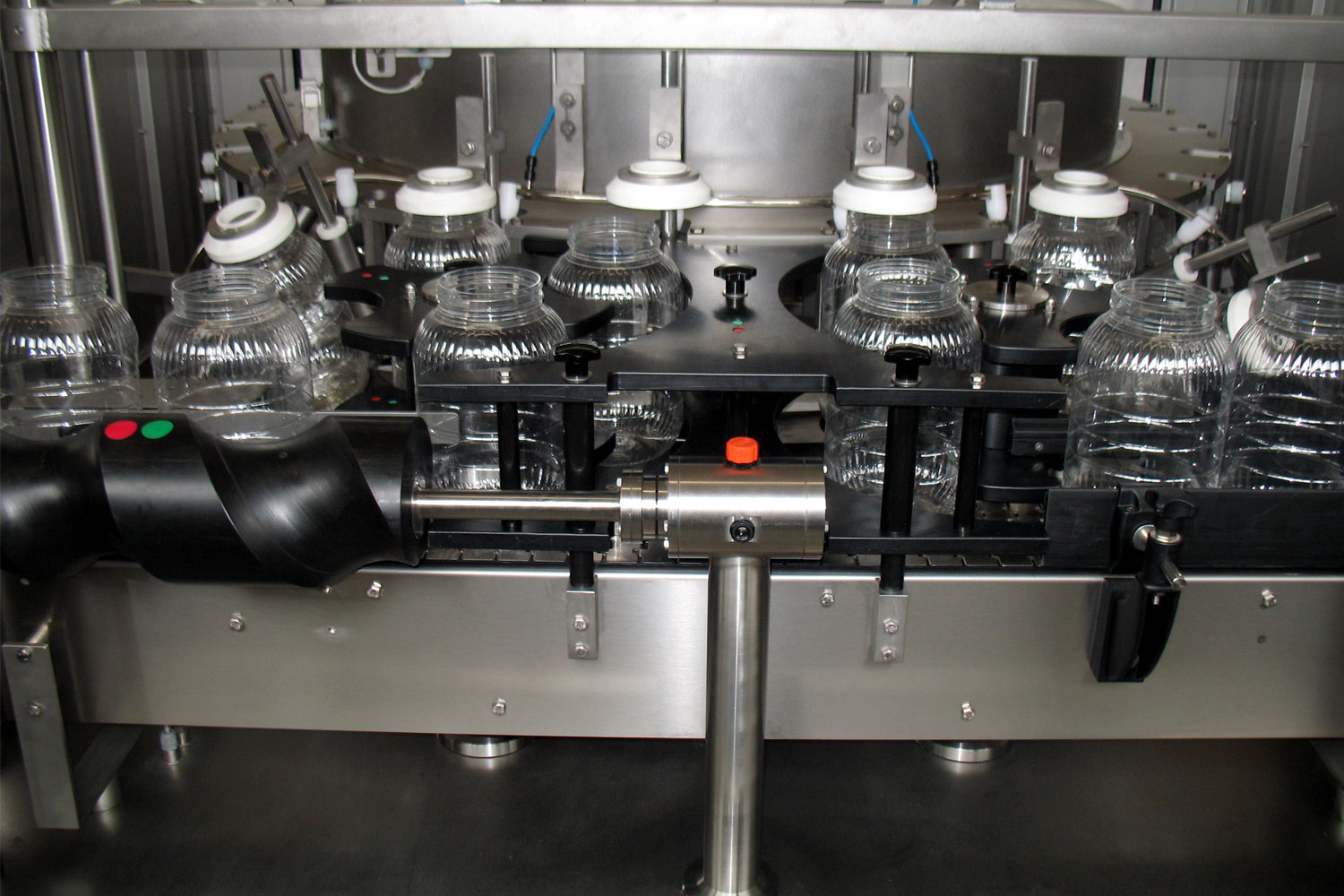

This type of gripper allows a quite safe hold and therefore handling of glass and plastic containers of any weight and shape or with big neck (ideal for jars and flasks)

The spraying nozzles can be both fixed or mobile, available in single or double treatment versions.

Blower for metal containers

Blower for PET containers

Rinser for glass bottles

BLOWING AND SUCTION

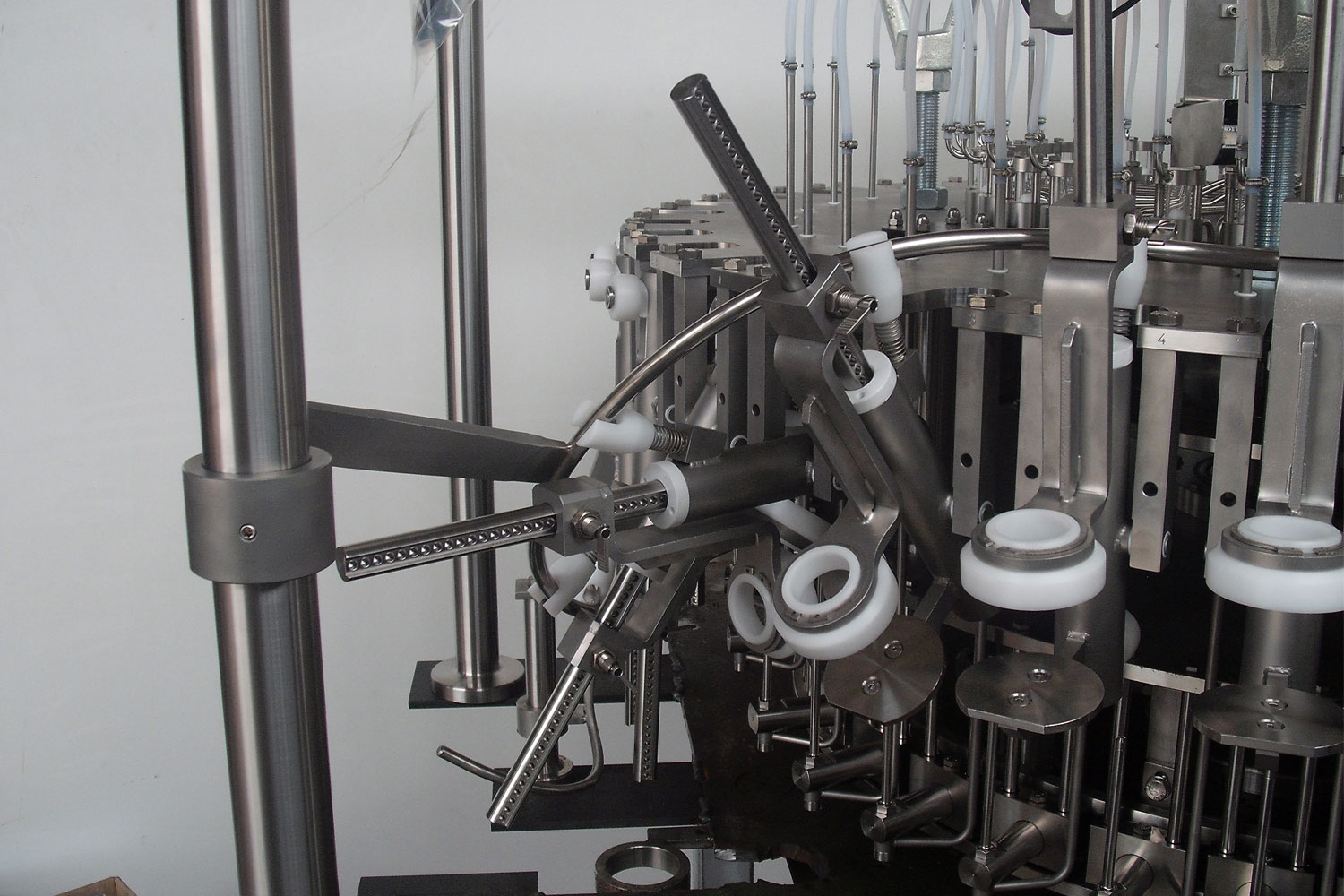

A first single blowing phase with sterile air is followed by a second blowing and suction phase alternately of air and particles which are removed by creating slight vacuum inside the bottle. This enables to increase considerably the blowing efficacy and grant a perfect cleaning of the container.

Gripper detail

Blowing and vacuum suction mobile nozzle

Ionized air blower machine

Fill in the form to receive all the details you need about all Promec bottling machinery

FILL IN THE FORM1R – Fixed and mobile

One rinsing phase with fresh water (to drain) or with sterilizing solution (water+ozone, water+sulphur dioxide, chlorinated water) followed by a drainage time dependant upon the acceptable residual water content.

1S (1S+1A) Mobile

One blowing phase with sterile air, sterilizing gas or steam to remove any dust or harmful gas from bottles and it is the case, make them sterilized. In order to remove the injected gas and any particles in suspension, it is possible that blowing and suction phases take place alternately. (1S+1A).

1R + 1S (1V) Mobile

One rinsing phase with fresh water (to drain) or with sterilizing solution followed by a blowing phase with sterile air to make easy the drainage, or with sterilizing gas (1R+1S) or steam to complete the container cleaning (1R+1V).

2R Fixed and Mobile (2 way)

One rinsing phase with sterilizing solution, either fresh or re-circulated, followed by a second rinsing phase with fresh water (to drain) and by a final drainage phase.

2S (1S+1V) Mobile (2 way)

One blowing phase with sterile air to remove any residual or harmful gas from bottles followed by a second blowing phase with sterilizing gas (2S) or steam in order to make container sterilized (1S+1V).