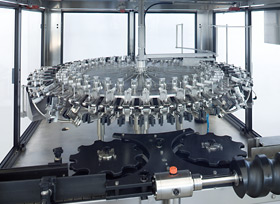

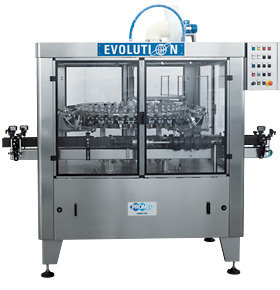

Through the flow control device (patented), linked to each spraying valve, it is possible to ensure that the nozzles are working properly and to check the efficacy of the cleansing fluid injection in each container treated, in order to guarantee thorough cleaning of the same. A spherical mobile element is installed on the feed pipe of each nozzle and it is activated “only and exclusively” when the washing fluid flows out of the respective nozzle; a special sensor, positioned in the rinsing (or blowing) area, verifies the correct position of the mobile element, and hence the optimal operation of the nozzle. If, on the other hand, the mobile element is not in the correct position, the malfunctioning of the corresponding nozzle is reported by means of an electric signal; this signal can operate an automatic ejection device of the bottle which has not been properly treated or it can stop the machine in a preset position so as to enable the operator to remove the unwashed container. This simple and efficacious system is particularly suited for applications in which it is of fundamental importance to guarantee that the containers have been treated (e.g. in the ULTRACLEAN and ASEPTIC sectors), so as to avoid problems relating to the contamination of the bottled product and the duration of its shelf life.

26 April 2021