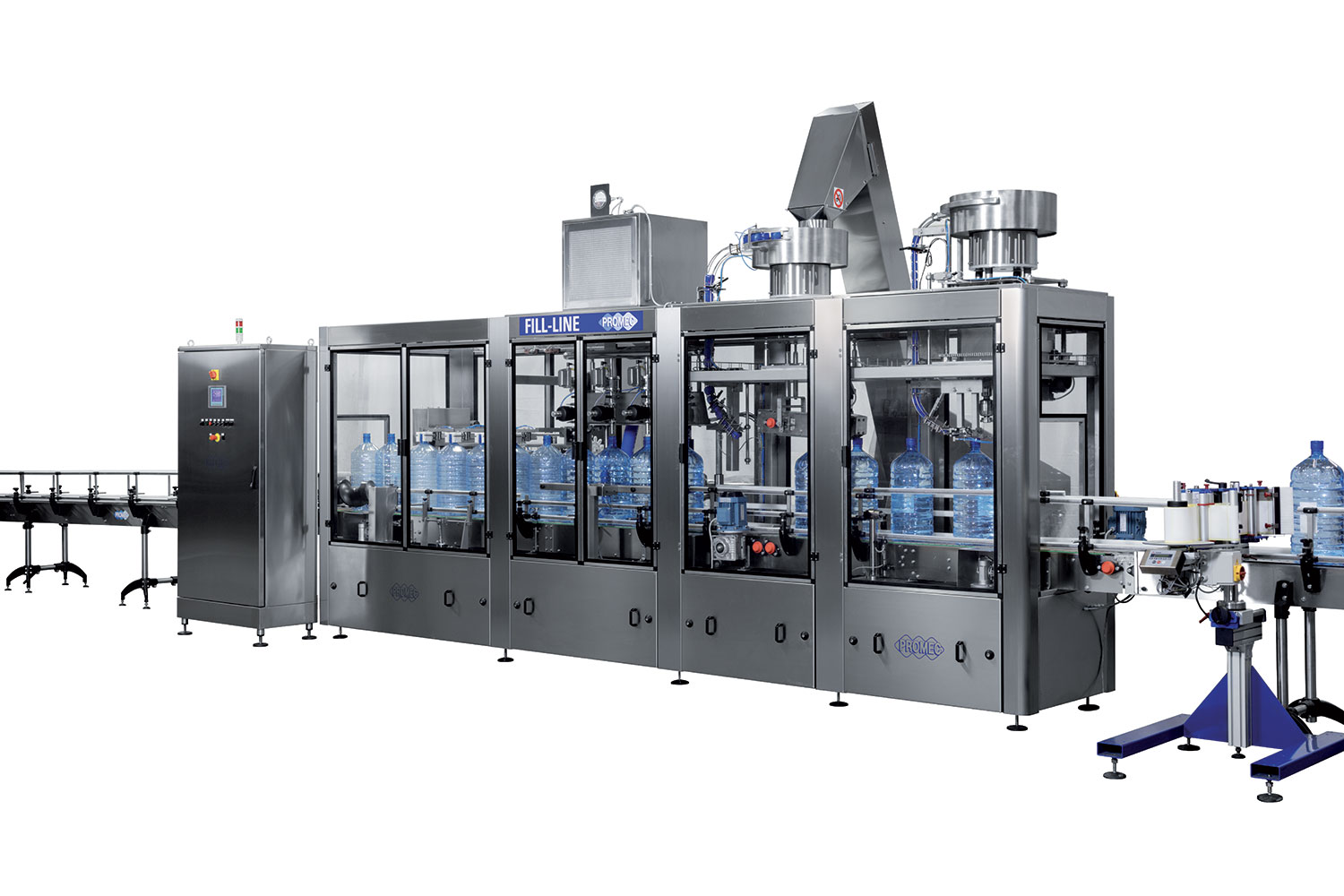

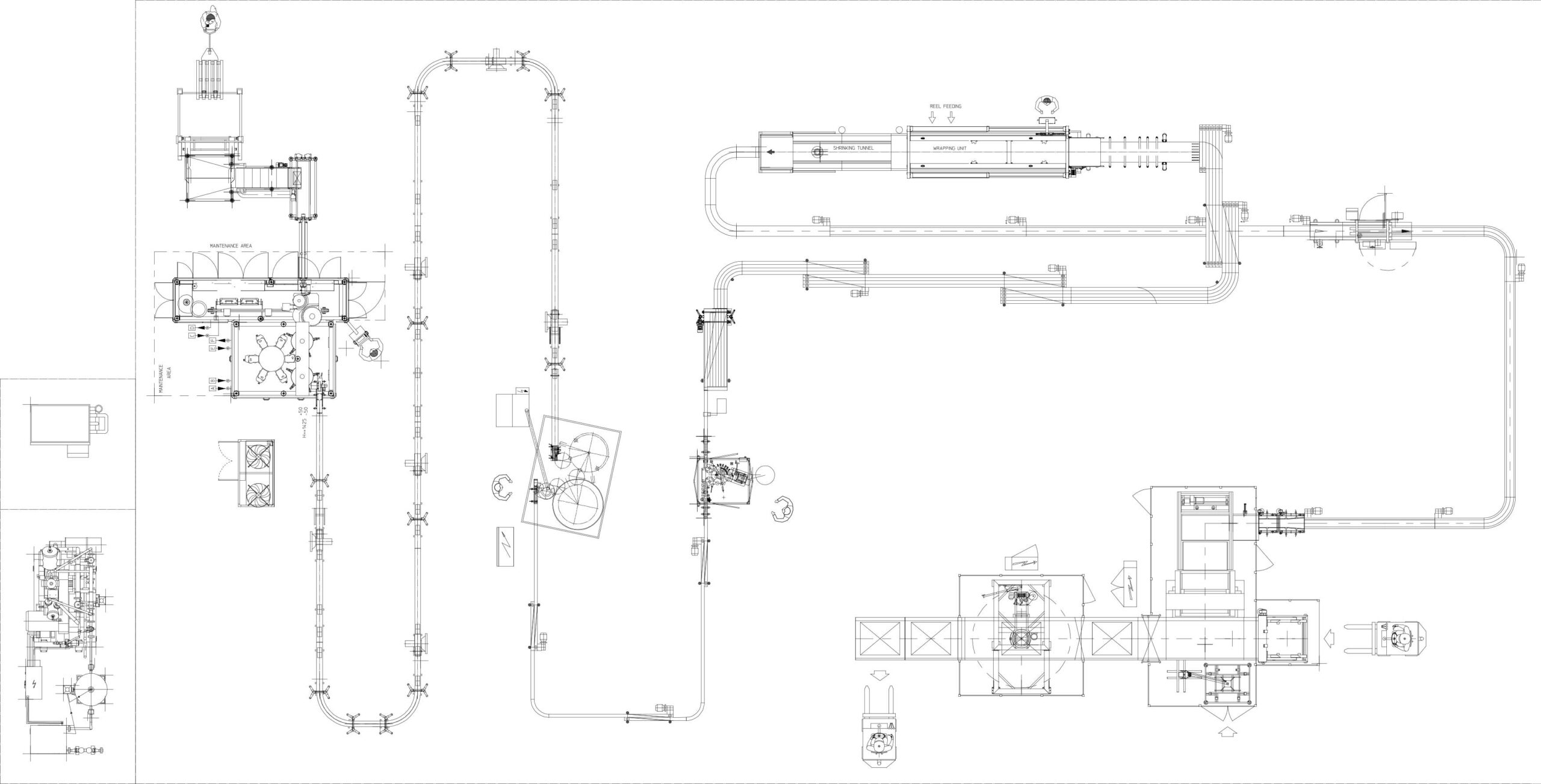

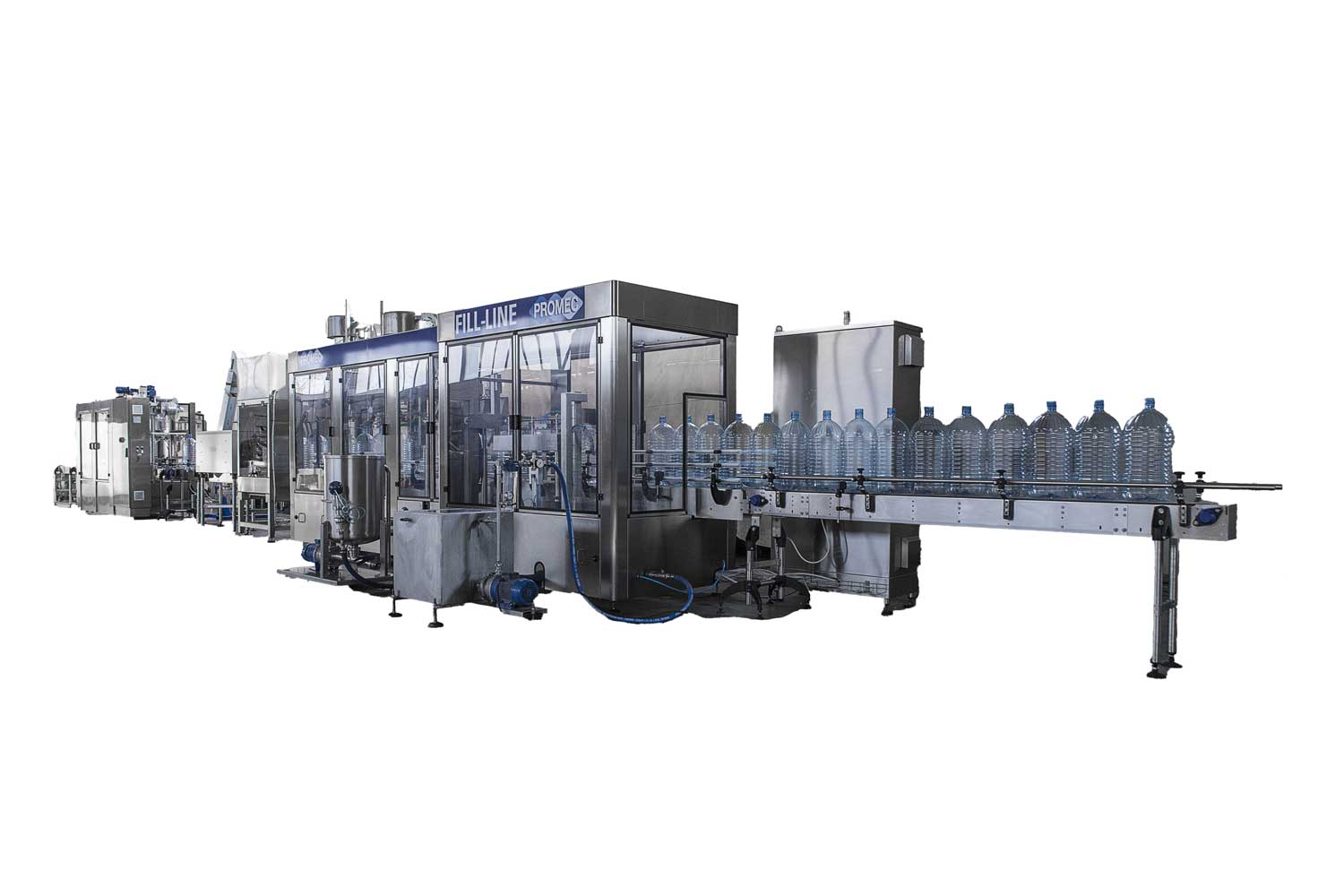

MULTIFORMAT FILL LINE LINEAR MONOBLOCKS FOR PRODUCTIONS UP TO 2.500 BPH OF 5 LT

It is a linear machine for filling PET or HDPE one way containers of large dimensions, from 5 up to 20 Lt; the modular structure allows to make up different kind of machines in a simple and cheap way, divided as follows:

- Rinser- Filler – Single capper (screw or pressure closure)

- Rinser- Filler- Double capper (screw or pressure closure)

- Filler- Single capper (screw or pressure closure)

- Filler- Double capper (screw or pressure closure)

Version n.3 and n.4 are used in case of bottles’ line blowing.

Each version is suitable for treating PET and HDPE bottles of different shapes and dimensions for a changeable production ranging from 300 up to 2.500 BPH, even in ULTRACLEAN version.

RINSING SECTION

The rinser is equipped with proper grippers, handling the neck of the bottle and placing the bottle over the spraying nozzles, available in single or double treatment too.

In the version with a single treatment, the bottle is rinsed using sterile water or other sterilizing solutions such as ozone or chlorine; in the double treatment version, the first nozzle sterilizes the bottle using proper sterilizing solutions (peracetic acid, H2O2, chlorine dioxide…) while the second one eliminates any residual of these substances through sterile water injection. The same machine can be used for the blowing version to clean the bottles with sterile air or ionized air, through appropriate nozzles designed by us.

Rinsing section

Filling

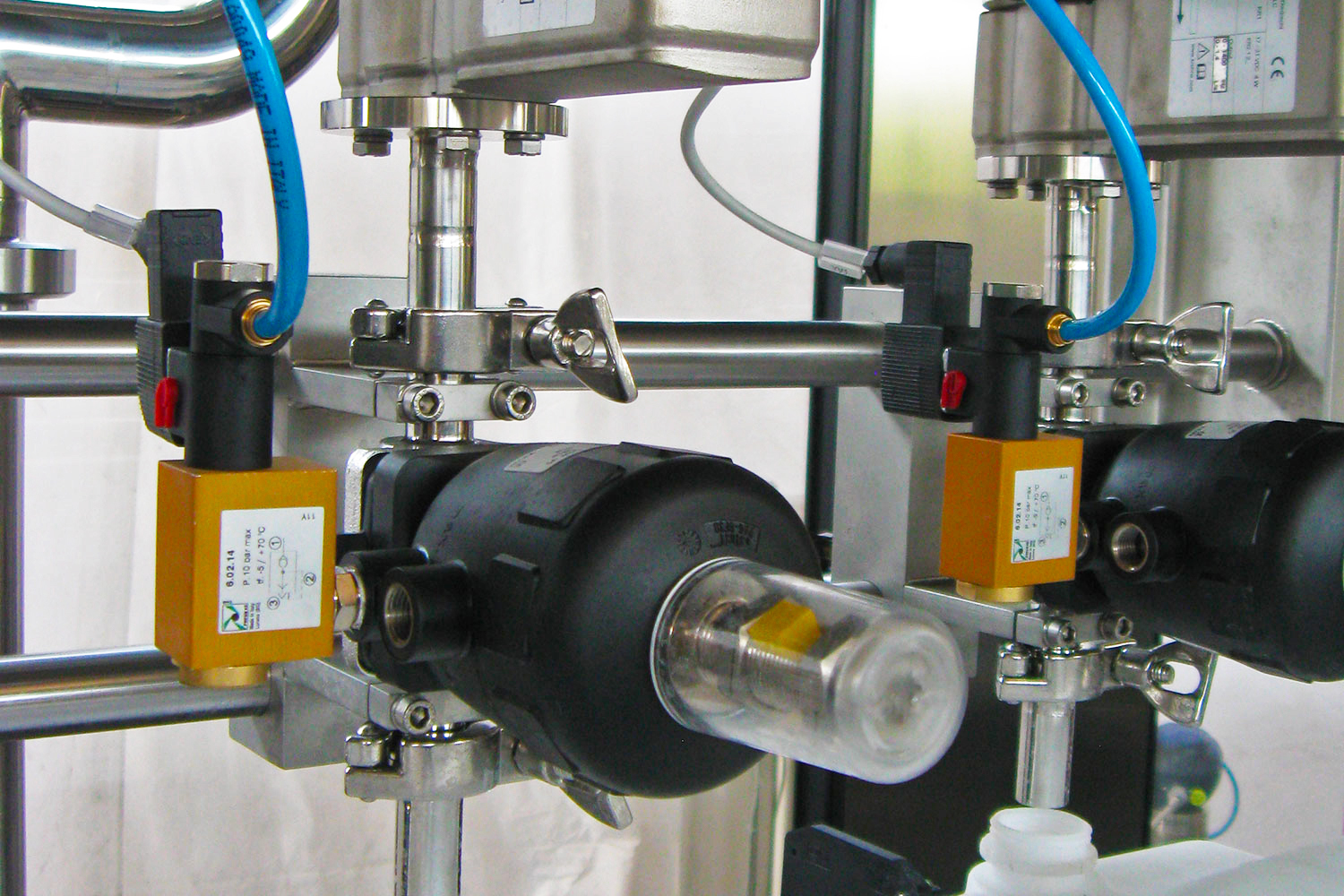

FILLING SECTION

The bottles’ filling is carried out by electromagnetic flow meters ensuring high filling precision and maximum hygiene of the system, due to the fact that there is no contact between the spraying nozzle and the bottle neck. The filling stage is regulated by a proper pump, driven by the PLC of the machine to perform the filling stages, in order to avoid any product leak and to optimize the filling time for any bottle format.

In the operator panel (touch screen ) the different filling programmes related to the different bottles’ formats are set.

Any format-changing related procedure is automatically run, setting the bottles’ format on the panel operator. The hydraulic circuit is made by AISI 316 stainless steel stiff piping, in compliance with the EHEDG regulations. Upon request, the bottle can be supplied with dummy bottles (automatic or hand run) to sterilize (C.I.P) the piping of the filling valve.

Filling valve

Filler with 4 filling valves

Filler with 6 filling valves

CAPPING SECTION

The capping stage is carried out in line as the previous ones. The capping can be carried out using pressure or screw closure; in both cases, a vibrating hopper is installed to direct the caps, as well as a letting down lane with pick-up head (in particular cases, the Pick and Place system can be installed).

In the pressure closure version, the machine is equipped with a closure tilted conveyor belt allowing a gradual closure of the caps, while the screw version, has a proper screwing pick-up head installed with a screwing couple adjustment device. In both cases, as optional, a caps’ sterilizing stage can be fit into the line (using ozone, H2O2 or other sterilizing solutions).

Pressure capper

Pressure capper for special cap

Pressure capper for special cap

Double head screw capper and pick & place system

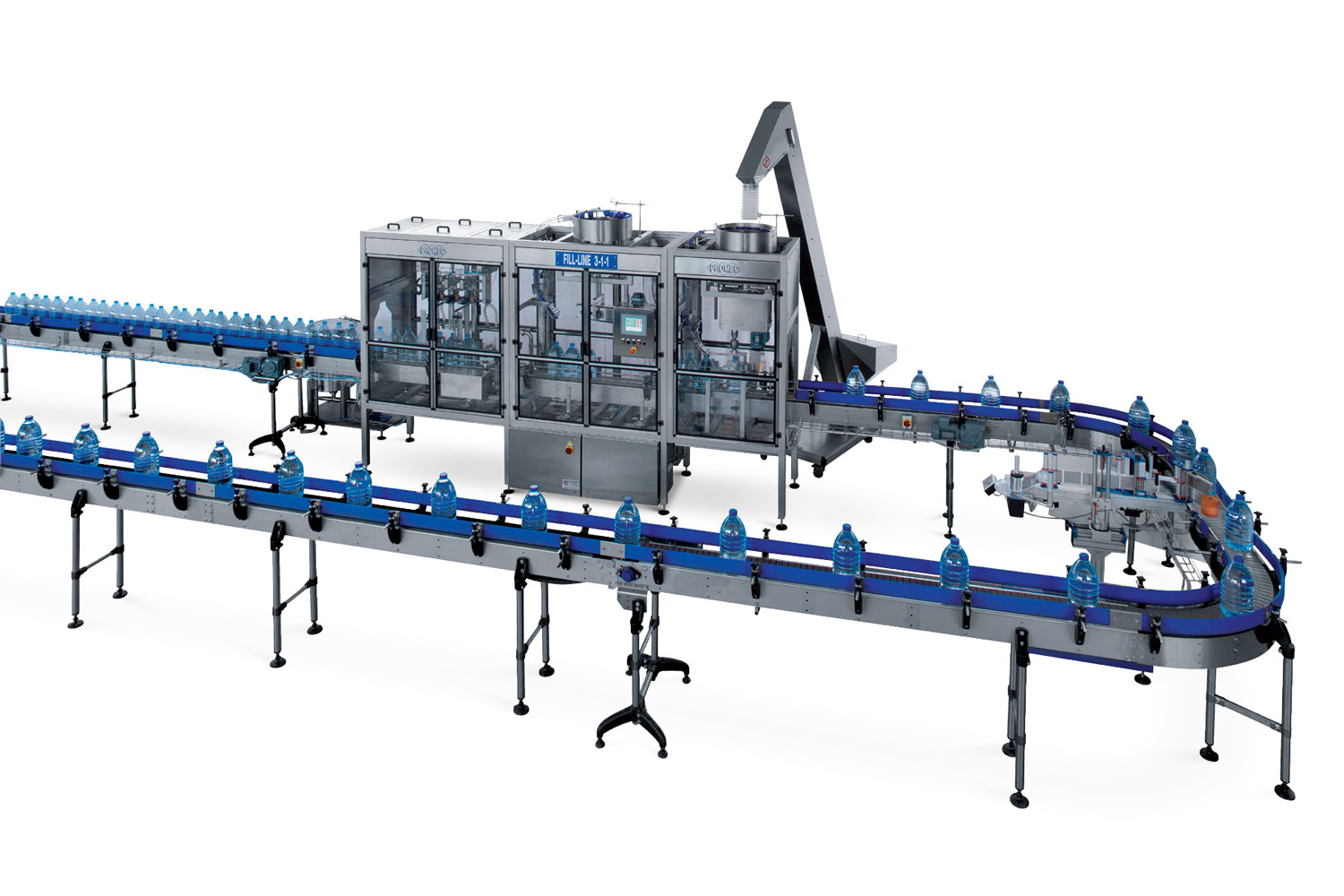

FILL LINE 3-1-1 LINEAR MONOBLOC

It is made up of a first filling section with three filling valves equipped with magnetic flow meters, the pressure closure capping section and the screw closure capping section. The format change is quick and designed to adjust the machine to different bottles’ formats (from 5 up to 20 Lt) with production up to 900 BPH of 5 Lt and 500 BPH of 5 gallons.

Single head screw capper

Volumetric filling

Filling

FILL LINE 4-1 MONOBLOC

It is made up of a filling section with four filling valves equipped with magnetic flow meters and a capping section for special caps equipped with a special device for water distribution. The cap has to be directed and moved by a special system (Pick and Place) studied and designed by Promec.

The line production is 450 BPH for 20 Lt bottles.

FILL LINE 6-1 MONOBLOC

It is made up of a filling section with six filling valves equipped with magnetic flow meters and a capping section for special caps equipped with a special device for water distribution. The cap has to be directed and moved by a special system (Pick and Place) studied and designed by Promec.

The line production is up to 650 BPH for 10 lt. bottles

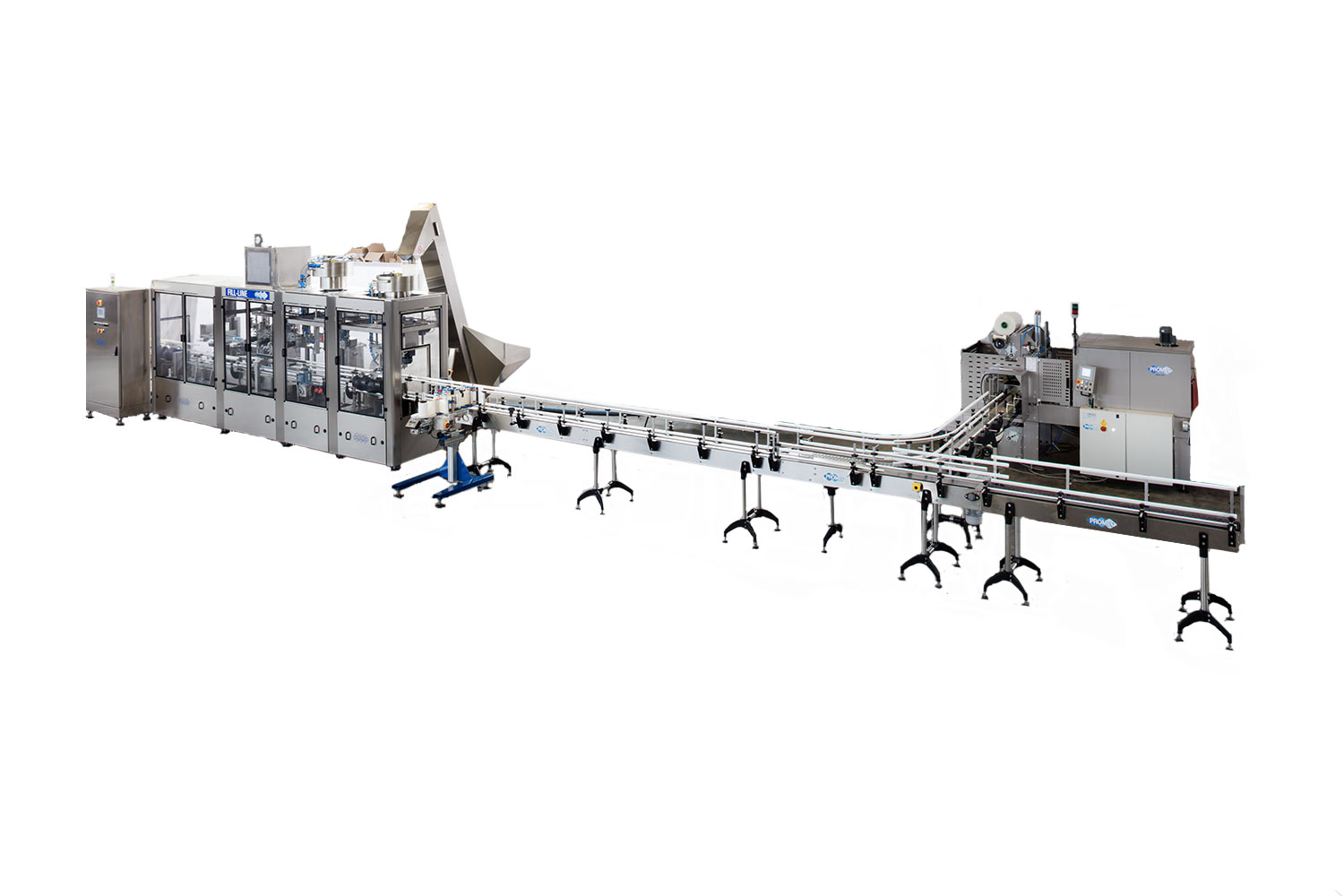

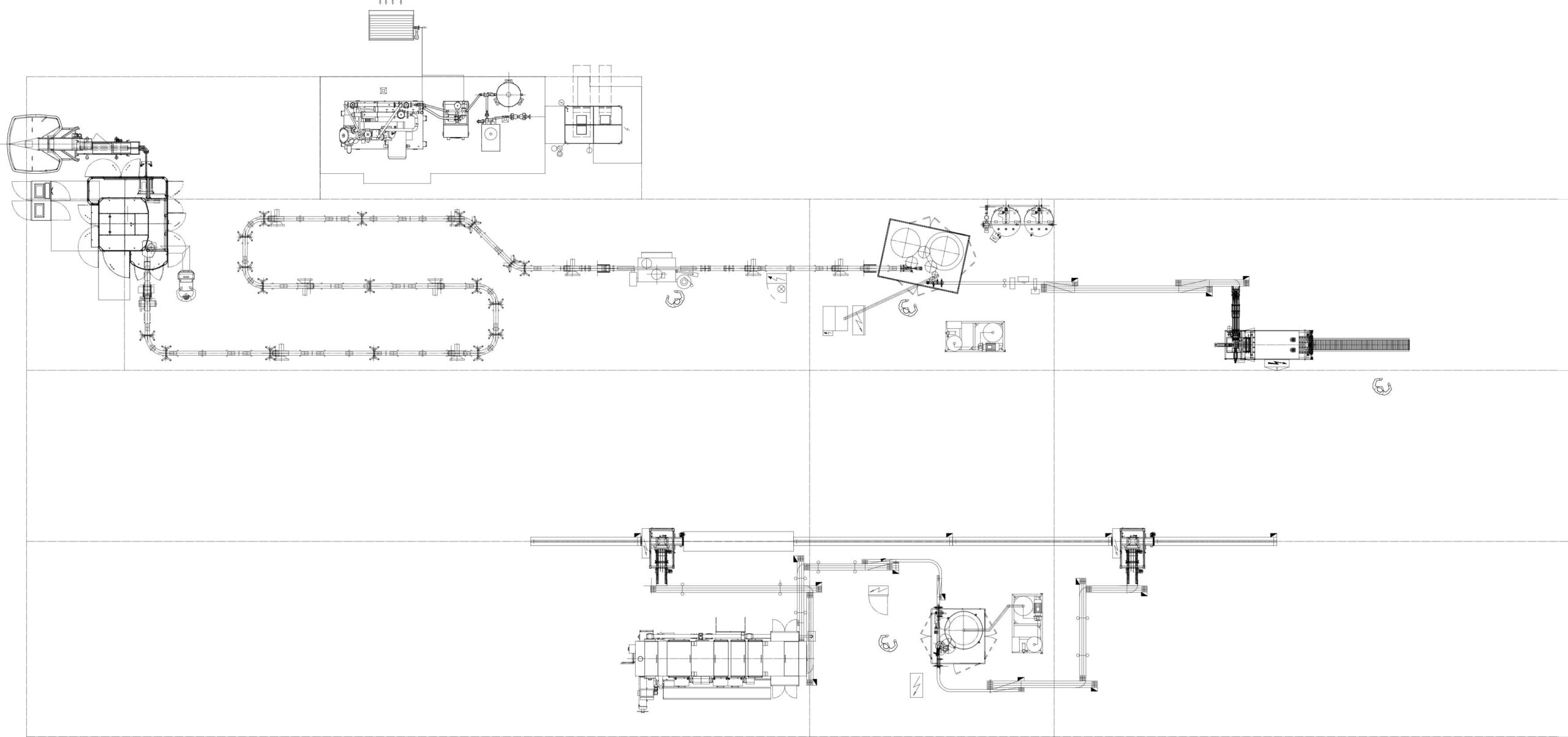

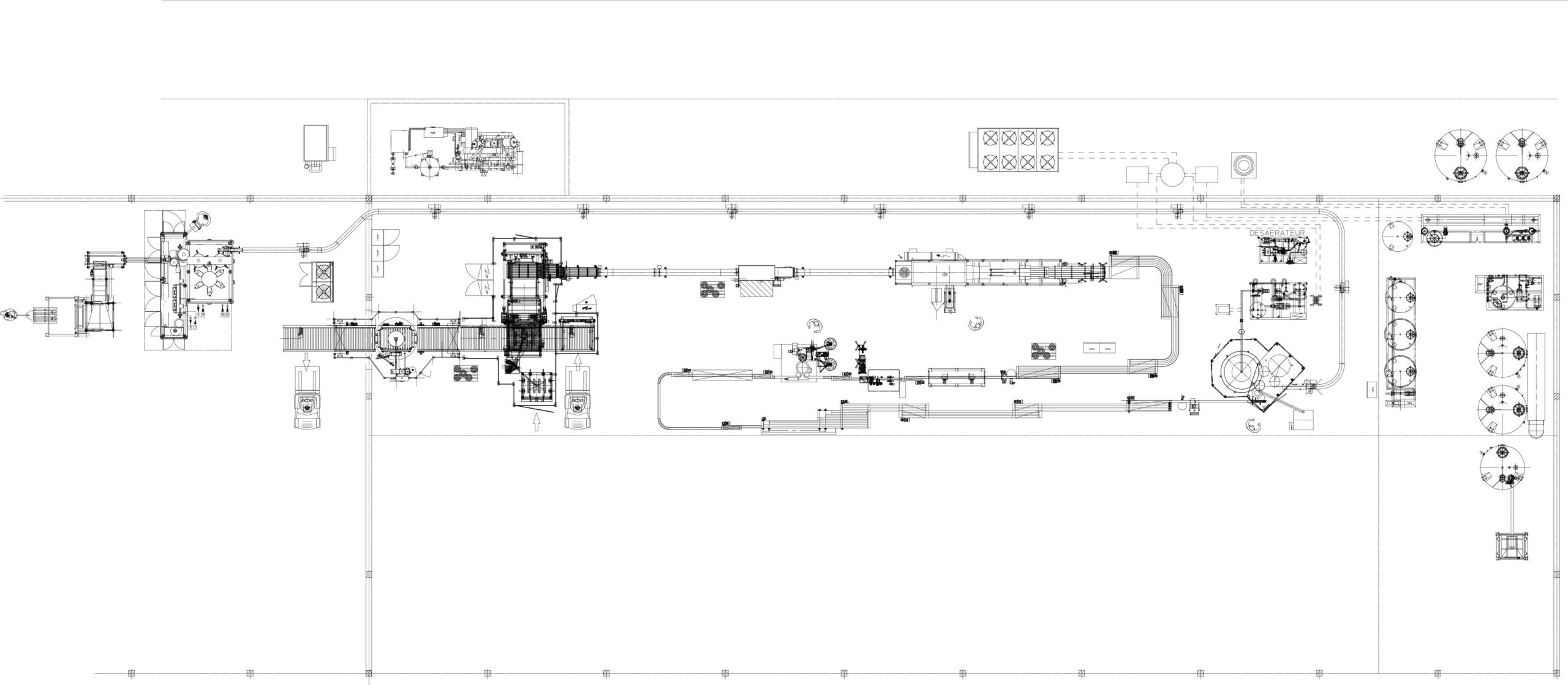

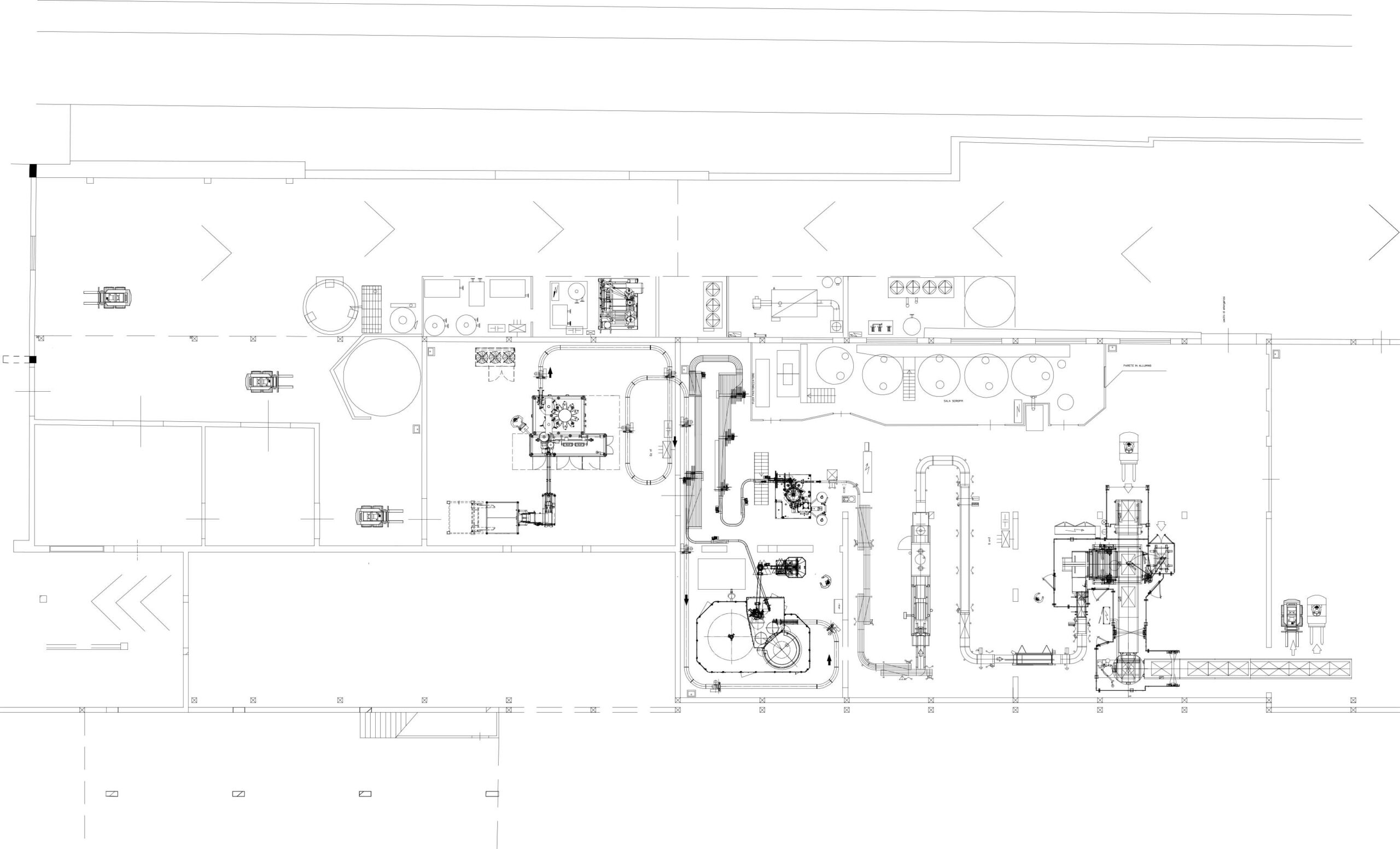

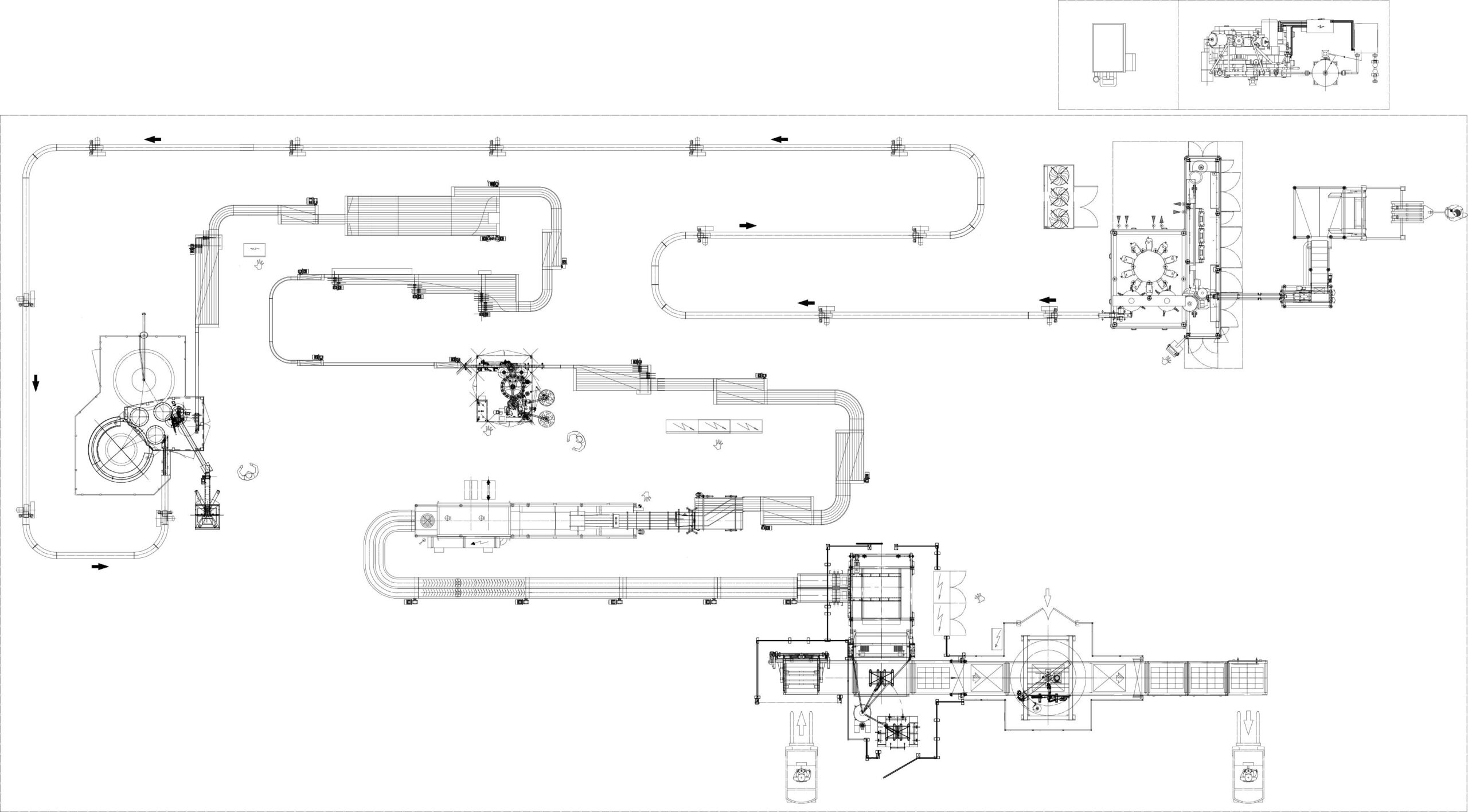

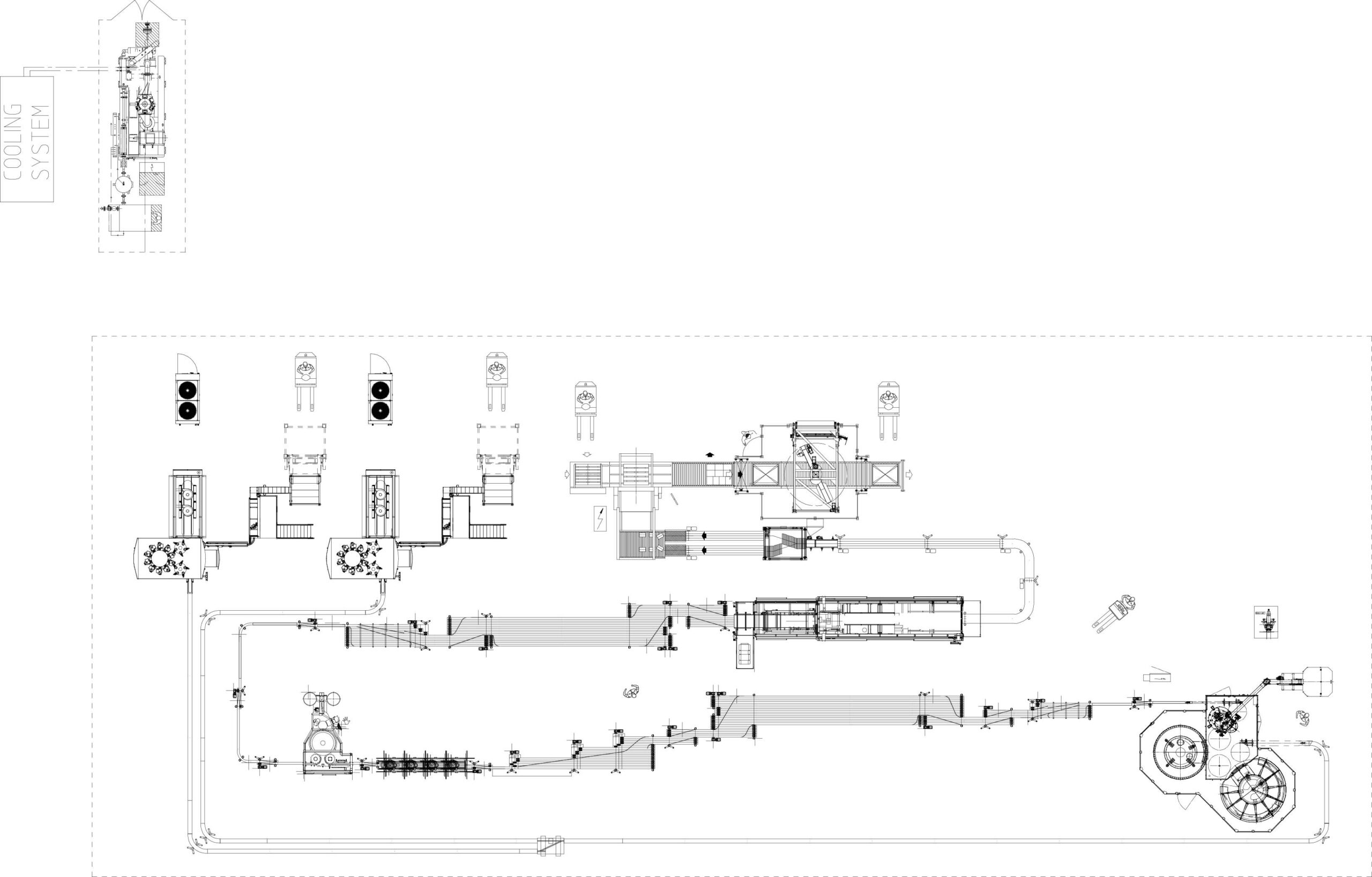

FILL LINE TRIBLOC 6-6-2

FOR 5 LT BOTTLES AND PRODUCTIONS UP TO 1500 BPH

Front view

Front view

Machine interior

Filler detail

Rinser detail

Pressure capper

Rinser

Filler

Screw capper

Fill in the form to receive all the details you need about all Promec bottling machinery

FILL IN THE FORM